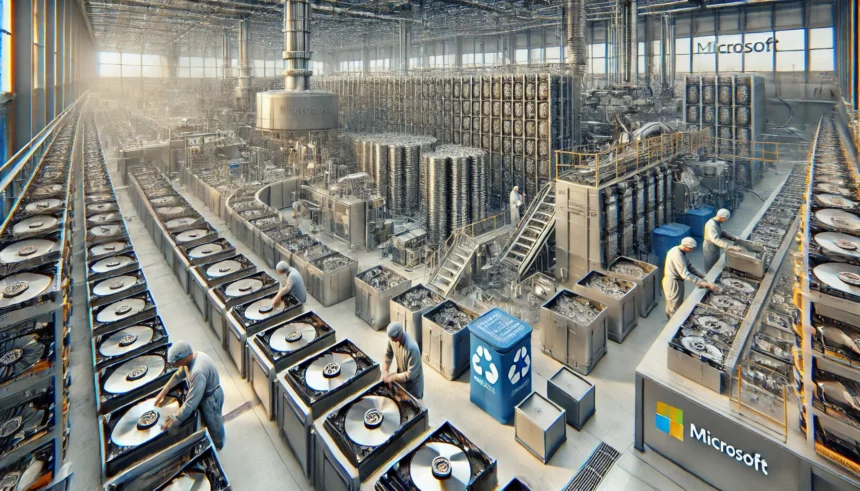

Microsoft has taken a big step toward a circular economy by investing in Cyclic Materials, a startup specializing in advanced metals recycling. This move, announced on July 16, shows Microsoft’s commitment to sustainable innovation, focusing on recycling rare earth elements (REEs) from old computer hard drives.

Cyclic Materials: A Leader in Recycling Technologies

Founded: 2021

Focus: Sustainable recycling technologies for REEs and critical metals

Cyclic Materials is known for its innovative approach to recycling, aiming to reduce the need for traditional mining and its environmental impacts. Their key technologies include:

- Mag-Xtract: Efficiently recycles rare earth elements from end-of-life products.

- REEPure: Handles recycling of copper, aluminum, steel, cobalt, and nickel.

- CC360: Specialized in recovering rare earths from discarded hard drives.

Why This Matters

- Environmental Benefits:

- Reduces water usage and waste

- Lowers carbon emissions compared to traditional mining

- Economic Impact:

- Creates a new value stream from disposed hard drives

- Supports the growing demand for rare earth elements

Microsoft’s Role and Goals

Investment: Part of Microsoft’s Climate Innovation Fund

Sustainability Goal: Achieve zero waste by 2030

Brandon Middaugh, senior director of the fund, said, “We’re excited to support a sustainable supply of rare earth materials with this investment.”

How It Works

Typically, hard drives are sent to IT asset disposal (ITAD) companies for data destruction and metal recovery, often leaving rare earth elements unrecovered. The introduction of CC360 changes this process by allowing ITAD companies to:

- Separate a portion of hard drives for rare earth recovery.

- Process separated magnets using Cyclic Materials’ technologies.

Benefits:

- Retains data security

- Adds value from reclaimed rare earths

- Reduces wear on shredders

Sean Magann from Sims Lifecycle Services (SLS) said, “This solution enables us to drive further value out of disposed hard drives while maintaining data security.”

Looking Ahead

With the opening of its Hub100 plant in Kingston, Ontario, Cyclic Materials is set to meet North America’s increasing demand for domestic sources of rare earth elements. Microsoft’s investment will help scale the deployment of CC360 technology, expanding commercial operations and enhancing recycling capabilities.

Industry Collaboration

This partnership is further strengthened by input from industry partners like SLS, which helped validate the new CC360 technology.

Cyclic Materials CEO Ahmad Ghahreman expressed his excitement, stating, “This support enables us to accelerate the deployment of our commercial facilities, which is a critical step in growing the domestic supply of rare earths in North America.”

Conclusion

Microsoft’s investment in Cyclic Materials underscores its commitment to sustainability and innovation. By supporting the development of advanced recycling technologies, Microsoft is helping to build a circular economy and reduce environmental impact.

This collaboration marks a significant step toward a more sustainable future, where valuable materials are efficiently recycled, benefiting both the environment and the economy.